The Vegas River Cruiser is designed with all the characteristics of a city apartment but with the capability of cruising the waterways, UK and European with simplicity.

The Vegas River Cruiser is also fitted with hydraulic steering to enable defined steering of the boat. They are built with a rounded square stern, lockers and a curved wraparound seating area to maximise the outdoor space.

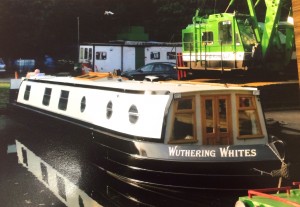

The Vegas River Cruisers are externally shot blasted (except base plate) to remove the mill scale, formed when hot rolled. Under the waterline is painted with a two pack epoxy blacking. Above the waterline is painted in a two pack paint system to provide prolonged impact & abrasion protection.

Fitted out using only the finest quality materials, including solid oak, by our team of experienced craftsmen, the Vegas River Cruiser offers excellent value for money with a very competitive price tag.

The layout of the River Cruiser from bow to stern is: Bedroom, Bathroom, 2nd bedroom (optional), Saloon followed by the Galley.

The River Cruisers are British built by ourselves from base plate to sign writing and come complete with a Recreational Craft Directive, Category D, full owner’s manual with operating instructions, issued by an independent surveyor and a 12 month warranty.

FITTINGS

Spray foamed and fully battened

Adequate ballast

18mm far eastern plywood flooring

Solid oak T & G on cabin sides throughout

Hull sides lined in 9mm oak faced veneered plywood

Painted ceiling in 9mm birch faced plywood

Ambiance flooring throughout

Hardwood trim throughout in oak

6 No 36” x 24” single glazed windows and 5 No 18” DBV portholes in a choice of finishes

Twin steel doors and sliding hatch to the stern with Yale security lock

All lining (except ceiling), cupboards and doors receive 3 coats of Goldspar satin varnish

Chrome mushroom vents to meet current RCD requirements

Hardwood window or porthole trims in oak

Chrome curtain poles and retainers or Venetian blinds to a colour of your choice

Stainless steel fresh water tank – 830 litres approx

Diesel tank – 800 litres approx

Waste tank – 585 litres approx

BEDROOM

Sapele ½ glazed bow doors

Steps to foredeck with tread, water pump and accumulator tank underneath

Fixed 5ft x 6ft 6” king size bed with memory foam mattress and oak headboard

Storage drawer under bed

One full height wardrobe

Two bedside cabinets

Chest of drawers

1 x radiator

4 No 18” DBV portholes

1 x mushroom vent

1kg fire extinguisher

1 wall light either side of bed

BATHROOM

Quadrant shower enclosure (800mm x 800mm)

Waterproof wall panels within shower enclosure

Thermostatic shower

Pump out toilet

Vanity unit with solid oak worktop and semi-recessed basin and taps

Chrome heated towel rail

1 x 18” DBV porthole with frosted glass

Extractor fan with LED light in the shower

CORRIDOR

Full height cupboard

Side doors

1 x radiator

SALOON

Large saloon designed for your own free standing furniture

Storage/entertainment cabinets with solid oak tops

2 x radiators

1kg fire extinguisher

4 x 36” x 24” windows

1 x mushroom vent

GALLEY

Solid oak doors and units with shelves

40mm solid oak worktops

Overhead cupboards to provide further storage by cooker hood

Stainless steel under-mount sink bowl and mixer tap and drainer grooves in worktop

Built in gas oven, grill and four burner hob

Cooker hood above hob

100mm splash back

Integrated 240V fridge

Integrated 240V freezer

Integrated 240V washing machine

2 x 36” x 24” windows

1kg fire extinguisher and 1 x fire blanket

1 x mushroom vent

Steps to stern deck with tread

ENGINE

Vetus 65hp 4 cylinder keel cooled engine, 3 or 4 bladed propeller to suit with ZF25 gearbox, MP22 standard control panel, 35mm water lubricated stern tube, 35mm shaft, 2” exhaust with lagging. One auto bilge pump.

HYDRAULIC STEERING

Within a console at the rear portside a Vetus KB450 steering wheel is fitted together with a rudder position indicator together with a Vetus hydraulic pump and hoses.

HEATING SYSTEM

Webasto 5kw diesel central heating system running 4 radiators and a heated towel rail through a 75 litre twin calorifier situated in the engine room.

240V SYSTEM

240V is supplied by a 3000w inverter/charger, shoreline power, socket and lead. 240V is supplied through a distribution panel with two ring main circuits and one immersion heater high load circuit. Boat protection is provided by a Victron galvanic isolator.

12V SYSTEM

12v power is supplied by 5 x 120 amp sealed for life batteries (upgrades available) charged from the engine alternator and inverter/charger to the main isolation switch and main fuse board onto DC switch/fuse panel to all circuits. Tunnel light and horn switched from rear deck control area. A choice of TV antenna or satellite cable fitted.

PAINT

The Vegas River Cruisers are painted in a two-pack system from the leading specialists in paint, International Paints. Primer, undercoat and top coat in Perfection is applied in two colours with coach line. Intertuf 362, a two-pack blacking is applied up to the top rubbing strake (except base plate). All decks, roof and gunwhales are sanded to provide a non-slip surface.

STEEL SPECIFICATION

10mm base plate welded both sides

6mm hull sides

5mm cabin sides

6mm roof

Our 5 tonne overhead crane allows us to handle cabin sides and the roof in lengths of up to 10 metres, thus reducing the welded seams on the boat.

Chine on hull sides

Square rounded stern with lockers and wraparound seating area

Two full length rubbing strakes and two intermediate strakes at bow, and two around the stern

Mild steel bollards at bow and stern (2+2)

Three recessed fender eyes on each side of the boat

60mm x 60mm x 6mm angle runs horizontally the length of the hull sides

60mm x 60mm x 6mm angle runs vertically every 4ft

T section handrail

Four anodes are also fitted to the hull

Curved seating area at bow

One pair of steel unglazed side doors in the corridor

Gas locker with gas bottle cradle at stern (gas bottle not included)

Air draught – 6ft from the base plate to the top of the steel roof approx

Upon completion of the steelwork the exterior of the hull (except base plate) is shot-blasted to Sa2.5. A two pack epoxy primer Interprime 820 is applied to all areas above the top rubbing strake. Two pack Intertuf 362 is applied to all areas below except for the base plate.